who's running them? what kind of ground clearance? im not lowered...did it really help the 60ft times? thanks

Relocation Brackets

siver rhyno

21 - 40 of 75 Posts

Joined

·

226 Posts

thanks for the info...now which ones steeda or bmr?

Joined

·

23,209 Posts

I'd say BMR.

Joined

·

120 Posts

If you would like, PM me and I'll give you a great deal on some Steeda ones.

The BMR ones are bolt in design, but that can lead to issues. This part should not be bolted in. The force of launching your car on a sticky set of tires puts a tremendous amount of force on these brackets as your lowers are being compressed on launch. That is why we choose to only made a Weld in version, to prevent any issues when launching. We've had Zero failures in 5+ years and over 1000 sets out there. The same can not be said for BMR.

The Steeda ones offer more adjustment and are made from thicker material.

The BMR ones are bolt in design, but that can lead to issues. This part should not be bolted in. The force of launching your car on a sticky set of tires puts a tremendous amount of force on these brackets as your lowers are being compressed on launch. That is why we choose to only made a Weld in version, to prevent any issues when launching. We've had Zero failures in 5+ years and over 1000 sets out there. The same can not be said for BMR.

The Steeda ones offer more adjustment and are made from thicker material.

Joined

·

254 Posts

This is why you should weld them in..

![Image]()

Joined

·

1,922 Posts

damn... I'll be tacking mine soon then. I have the UMI bolt-ins and no issues, but soon I'll have 305 555r out back and things might change.

Joined

·

108 Posts

I vote UMI!

I was pleased to see the 1.5 tenth 60' improvement in a previous thread.

Thanks for the UMI love guys.

ramey

I was pleased to see the 1.5 tenth 60' improvement in a previous thread.

Thanks for the UMI love guys.

ramey

Joined

·

120 Posts

I even adapted the Steeda ones onto my personal Fox. 1.31 sixty foots are NO Problem for these brackets, on Drag Radials....

![Image]()

Joined

·

254 Posts

One good launch is all it will take!!damn... I'll be tacking mine soon then. I have the UMI bolt-ins and no issues, but soon I'll have 305 555r out back and things might change.

Joined

·

22,072 Posts

Sort-of. You want to make sure that the arms don't come above parallel under the suspension compression you see under acceleration. That means that at rest, the arms should slightly slope upward from the axle to the body.Take a look at your lower control arms. If they are already parallel to the ground, you don't need relocation brackets.

Joined

·

1,280 Posts

That picture is an old BMR Design. We recommended they be welded in, as that design should have been really; especially on a set-up like the one pictured with Adjustable drag shocks and sticky Mickeys. I would be willing to bet, that happened on the track.

Now, our new design has been tested thoroughly. Our's are not welded on our test car, and have survived (and worked well) with very good sixty foot times.

They have also been tested on a 1,000 HP (LOW 9 SECOND) S197 that launches on a 2-step at over 5,000 RPM. Bolted in and not welded.

That being said, I generally always recommend them being welded on a "serious" combination, no matter the design; if the car will be going to a drag strip with sticky rear tires. But, I assure anyone reading this, you will NOT bend or break our CAB005 if they are installed and torqued correctly.

Thanks to some of you for the compliments!

Now, our new design has been tested thoroughly. Our's are not welded on our test car, and have survived (and worked well) with very good sixty foot times.

They have also been tested on a 1,000 HP (LOW 9 SECOND) S197 that launches on a 2-step at over 5,000 RPM. Bolted in and not welded.

That being said, I generally always recommend them being welded on a "serious" combination, no matter the design; if the car will be going to a drag strip with sticky rear tires. But, I assure anyone reading this, you will NOT bend or break our CAB005 if they are installed and torqued correctly.

Thanks to some of you for the compliments!

Joined

·

1,280 Posts

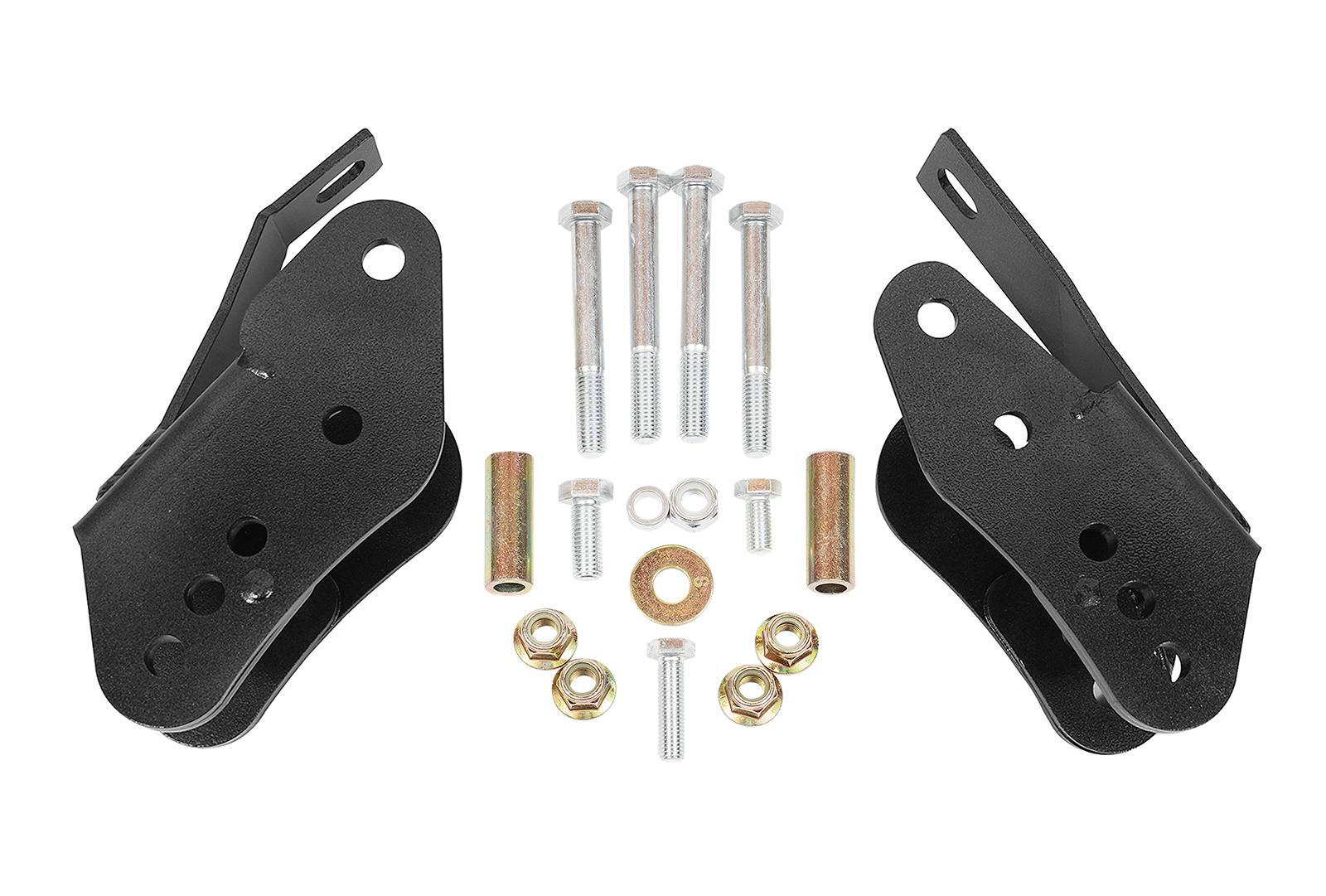

Here is our current design that has had zero failures, and is the only bolt-on set of LCA Relo brackets that has proven to work successfully on Matt Dasilvas 7,000+ RPM Launching machine!

![Image]()

![Image]()

![Image]()

![Image]()

Here is the car we have tested them on. He still utilizes a FULL BMR Suspension, from front to back.

![Image]()

Here is the car we have tested them on. He still utilizes a FULL BMR Suspension, from front to back.

Joined

·

1,922 Posts

well, so far I've never had a good launch.... Sumitomo FTLOne good launch is all it will take!!

Hopefully with the 555r's I can see how quick this thing really is...

Joined

·

120 Posts

Here is our current design that has had zero failures, and is the only bolt-on set of LCA Relo brackets that has proven to work successfully on Matt Dasilvas 7,000+ RPM Launching machine!

Good thing they were redesigned cause the last set that was on Matt’s car left him stranded at the season opener in Bradenton this year...

Joined

·

2,516 Posts

Were you up on Parmer the other day? I saw a car that looked like yours.well, so far I've never had a good launch.... Sumitomo FTL

Hopefully with the 555r's I can see how quick this thing really is...

Joined

·

1,922 Posts

nope! Parmer might as well be oklahoma as far as I'm concerned. I'm a dirty southsider. we need to meet up sometime.

Joined

·

10,549 Posts

wow seems like this thread turned into different manufacturers having a pissing contest.

Joined

·

2,516 Posts

Well I still need to do these headers...nope! Parmer might as well be oklahoma as far as I'm concerned. I'm a dirty southsider. we need to meet up sometime.

When it warms up a little, come up

Joined

·

1,922 Posts

If you don't get those headers in soon, Zippy is going to cut up your MM card...Well I still need to do these headers...

When it warms up a little, come up

Joined

·

1,280 Posts

Are you assuming that Matt was using our Relocation Brackets at Bradenton?Good thing they were redesigned cause the last set that was on Matt’s car left him stranded at the season opener in Bradenton this year...

Matt has not ever had an issue with a BMR part. The Relocation Brackets that he has broken, were not ours...............

21 - 40 of 75 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 6.3M

- members

- 83K

- Since

- 2005

A forum community dedicated to all Ford Mustang owners and enthusiasts. Come join the discussion about performance, racing, builds, modifications, troubleshooting, maintenance, and more!

Explore Our Forums

Top Contributors this Month

View All

Jrpbrannon

5 Replies

Metaltron83

4 Replies

Mustang wheel

2 Replies