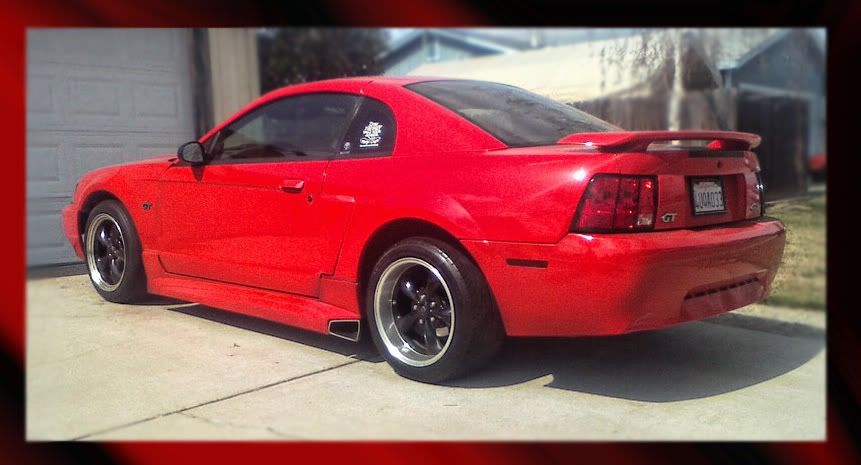

I had just completed a 200 mile trip. I take very good care of my ride. Oil, coolant, detailing inside, outside, motor bay... all that.

Car only has 100K miles on it. Its always run strong. Never had any problems.

I went to start the car up and heard a noise like air was shooting out in small spurts almost from the passenger side glove compartment. WTF?

I open the hood, stand at the passenger side and I reach to the sparkplug connector that is the second one from the firewall. I turn it, and the ticking stops.

I'm not a mechanic mind you. I can do oil changes, tires, batteries, simple ****... maybe a little more.

Its a 2001 GT V-8 4.6 manual. I figure out how to pull the plug cover. The whole plug comes out. The sleeve is still connected to the plug, but I don't know this until I buy the new plug and see the width difference.

I put the old plug (with sleeve of course) back into the deep-ass hole...geez ~ and I wrench it very slowly and carefully. I cannot believe it. It actually tightens up! WTF?

What made it come out? The threads were not stripped? I put everything back together. Had to remove the rail cover because it was almost directly over the sparkplug hole. Pulled the intake and all that shiz.

Put everything back together and I runs like a charm. Took it out on the highway and got on it just to make sure.

I still have my fingers crossed b/c now I feel like I should have all the plugs replaced or looked at.

Any ideas? Is this a common problem? What made that plug come out if the sleeve threads were NOT stripped?

![Image]()

Car only has 100K miles on it. Its always run strong. Never had any problems.

I went to start the car up and heard a noise like air was shooting out in small spurts almost from the passenger side glove compartment. WTF?

I open the hood, stand at the passenger side and I reach to the sparkplug connector that is the second one from the firewall. I turn it, and the ticking stops.

I'm not a mechanic mind you. I can do oil changes, tires, batteries, simple ****... maybe a little more.

Its a 2001 GT V-8 4.6 manual. I figure out how to pull the plug cover. The whole plug comes out. The sleeve is still connected to the plug, but I don't know this until I buy the new plug and see the width difference.

I put the old plug (with sleeve of course) back into the deep-ass hole...geez ~ and I wrench it very slowly and carefully. I cannot believe it. It actually tightens up! WTF?

What made it come out? The threads were not stripped? I put everything back together. Had to remove the rail cover because it was almost directly over the sparkplug hole. Pulled the intake and all that shiz.

Put everything back together and I runs like a charm. Took it out on the highway and got on it just to make sure.

I still have my fingers crossed b/c now I feel like I should have all the plugs replaced or looked at.

Any ideas? Is this a common problem? What made that plug come out if the sleeve threads were NOT stripped?